Lithium Iron Phosphate Battery Care

The NEW China Aviation Lithium Battery Company CA series cells provide an advance in

nanoparticle lithium iron phosphate cell technology featuring starkly improved cold weather

performance, increased power output and greater cell to cell capacity consistency than ever achieved

by any Chinese battery manufacturer. The increased power capability means less voltage sage for any

given current output. The improved capacity consistency makes managing a series string much easier.

These cells are inherently safer with much higher thermal runaway temperatures than the Lithium

Manganese and Lithium Cobalt metal oxide cells used by many automakers. We think these

advantages make this cell the choice worldwide for electric vehicle applications. They are the only

battery cell we carry at Octopus Electrical Service

CARE AND FEEDING OF YOUR CA SERIES CELL

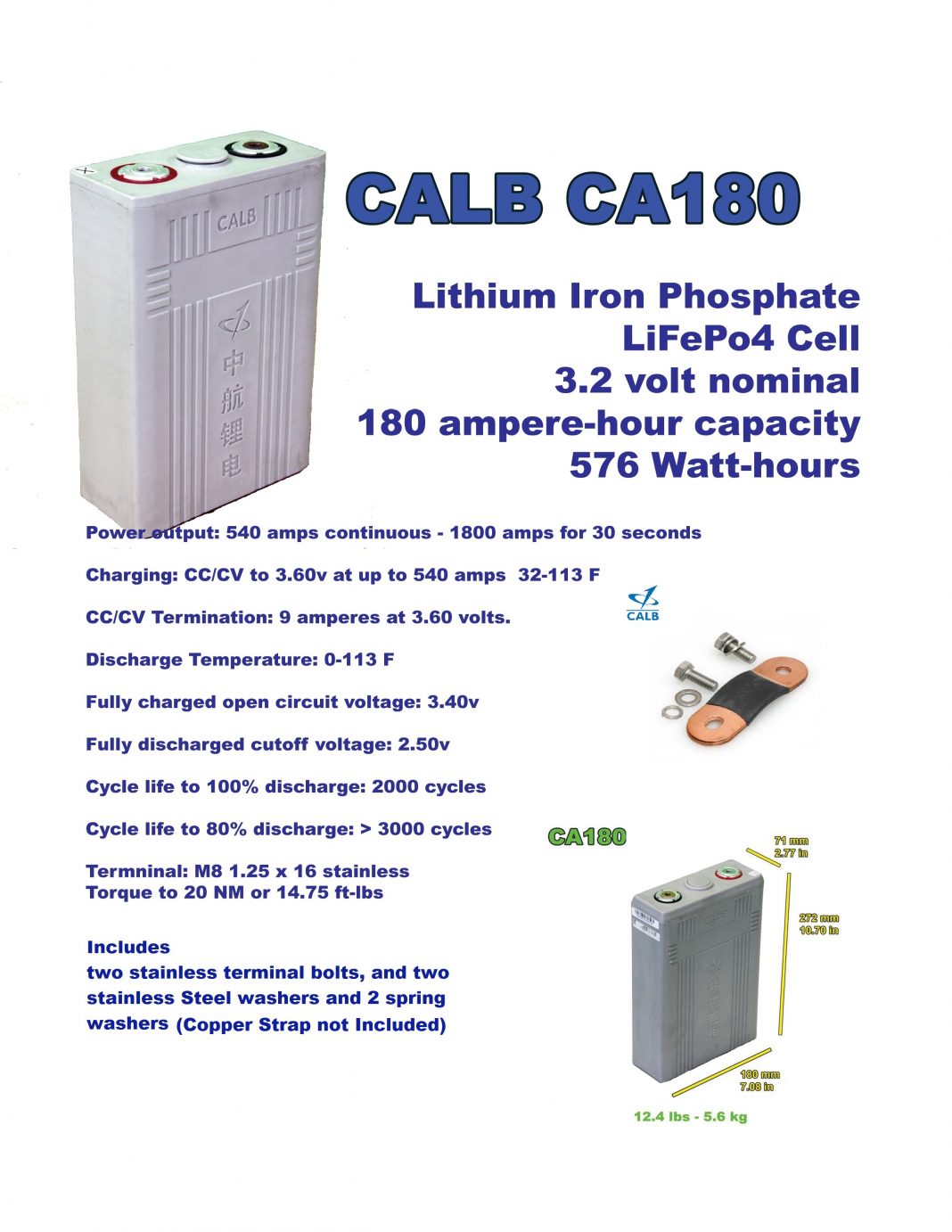

The new CA/FI series cell incorporates some nano-scale improvements in cathode and anode materials along with some significant improvements in electrolyte chemistry that represent the absolute peak of performance in LiFePo4 ionic battery technology. With a recently completed modern manufacturing facility, the China Aviation Lithium Battery Company has achieved production consistencies heretofore unachievable. The result is the new “grey cell”

the CA/FI series. CA is an abbreviation of the China Aviation Lithium Battery Company (CALB). FI is a series abbreviation for iron phosphate (FePo) chemistry series I. This is their first series newly designed and manufactured subsequent to their acquisition of the Sky Energy Battery Company – the previous SE series. The China Aviation Missile Academy purchased this company, and subsequently invested nearly a billion dollars in new plant and manufacturing to form the China Aviation Lithium Battery Company. The new FI series offers some serious advantages over previous cells. They produce significantly more power than previous cells with a rating of 3C continuous output and brief outputs of up to 30 seconds at rates up to 10C. A CA180FI cell can produce 1800 amps with minimal voltage sag.

The cells feature improved cold weather performance. Longer cycle life. And due to better capacity consistency, they are easier to manage in serial strings. Common wisdom regarding the care of lithium batteries requires a battery management system.

The basic rule is do NOT overcharge these cells and do NOT over discharge them. Observing those two precepts will ensure many years of service. If you fail to observe this, even once, it will most likely result in cell destruction and loss, and it will absolutely lead to early capacity loss of your pack. But achieving this takes a bit of strategy.

The Battery Management System or BMS

We at OES have always fitted a Battery management system to all our batteries, the BMS shuts the battery down if the voltage on any one cell falls below a set figure (usually 2.5v) and it also shuts the battery off if any cell goes over a set figure (usually 3.7v) also it keeps each of the cells within the same voltage range. IE. if one cell is too full then it places a 1 amp load across that cell until the voltage drops to the set figure (again usually 3.5v)

The BMS takes the hassles out of managing these LFP batteries and is HIGHLY RECOMMENDED. Its very easy to damage one cell with a high or low voltage without knowing it if you dont have a BMS installed.

TOP BALANCING.

The cells do not actually drift apart from each other with regards to state of charge usually. And the top balancing process brings all the batteries up to the same level of charge.

How To fully charge the LFP batteries manually without a BMS ,

The charge process for LiFePo4 cells involves charging at a fixed current until a specific voltage is reached, and then holding that voltage until the current decreases to a certain minimum value. This is termed a Constant Current (CC) / Constant Voltage (CV) charge curve.The CC/CV charge curve really has little to do with the actual battery voltage. The true open circuit voltage of the cell is nominally 3.38v and cannot be measured until some HOURS after the charge procedure.

For Manual Charging without a BMS control system

The CC/CV charge process is a PROCEDURE – a recipe that if followed carefully, will RESULT in a fully charged cell. The basic recipe is:

1. Charge at a fixed current of 0.5C until the cell terminals measure 3.600v

2. Hold the voltage precisely at 3.600v decreasing current as necessary. As the cell adds energy, the voltage will naturally rise. The current will have to be decreased to hold the voltage down at 3.600v

3. When the current has reduced to 0.05C, TERMINATE ALL CHARGING. Within a few hours, you should measure something in the range of 3.35 – 3.38v on the cell terminals. THIS is the cell voltage. The 3.600 was a procedural measurement. NOT a cell voltage. So for a 180Ah cell, you would charge at 90 amps to 3.600v and terminate when the current decreases to 9 amps. For most of us, this procedure is not perform-able. Your chargers might manage 15 or 20 amps. But the procedure is reasonably flexible. To account for this, and to intentionally UNDERCHARGE our cells a bit to maximize cycle life, we at OES NEVER charge over the full 3.65v. We normally use this procedure to a measured 3.50v to 3.60v and we’ve had very good success with this. At the low current levels we can accomplish, the charge curve is so steep that little additional energy is actually put into the cells between the 3.50v and 3.60v marks in any event. So little capacity is lost. But a lot of problems are avoided.

HOW to BOTTOM BALANCE (Note we at OES do not do this) as its very time consuming.

And you also do it at the BOTTOM of the charge curve.

1. Discharge each cell individually at a low current level of 30 amps until the cell measures 2.50v.

2. Allow the cell to rest overnight.

3. The cell voltage will “bounce” or recover to some value in the 2.75 to 2.85v range.

4. Discharge the cell for an indication of 2.65v.

5. Allow it to recover again for 30 minutes.

6. Continue this process until a stable reading of 2.75 volts has been achieved.

7. For cells lower than 2.75, you may need to add energy from a 5v or 12v power supply to bring them up to 2.75v.

8. Once all cells are stabilized at 2.75v, assemble your battery pack in a series string in your vehicle.

9. Charge the string using CC/CV to 3.5v X the number of cells in string. Ie, 10 cells in series would be charged to 35volts.

10. AFTER charging, this string should settle to about 33.4v – essentially 3.34 v per cell. Your pack is at this point fully balanced and fully charged. It is relatively easy to build an inexpensive device to help bleed cells using a 250 watt 0.1 ohm resistor with some terminal clamps. This will bleed individual cells at a rate of about 30 amps.

Battery Strapping

This strapping system is very effective but in some very subtle ways. Strapping batteries is actually a terribly important element of battery care because the cells are rarely installed in indoor static environments. The Marine environment is actually a bit of a challenge. And it is worthwhile to expand on this a bit.

1. With a fine sanding block or garnet sand paper, lightly burnish the cell terminals. The positive terminal is the inner circle of aluminum while the negative terminal (anode) has a copper inner ring. Polish these to a high shine. This removes surface oxidation from the terminal significantly improving conductivity.

2. The copper strap has two sides. The top side features rounded edges on the terminal bolt slot. The bottom side has a sharp edge on the terminal bolt slot. Use the sanding block to lightly burnish the bottom side in the terminal bolt area. Just lightly buff the surface, again to remove microscopic oxidation.

3. Position the strap bridging the positive terminal of one cell to the negative terminal of the next cell.

4. Insert a stainless steel terminal bolt with SA/S washer and Lock Washer into each terminal bolt hole. Do not tighten until both bolts are installed to avoid flopping the strap around to other terminals.

5. Once each bolt is carefully threaded, use a 13 mm or ½ SAE socket wrench to tighten terminals. On CA180FI cells this should be tightened to 20 newton meters or 14.5 inch lbs.

This strapping system is very effective but in some very subtle ways. Strapping batteries is actually a terribly important element of battery care because the cells are rarely installed in indoor static environments. The MArine environment is actually a bit of a challenge. And it is worthwhile to expand on this a bit. Most metals have an interesting feature in that as they carry large current loads they heat. As they heat their resistance to current flow actually increases. Unfortunately this causes more heat. Which causes more resistance. Terminal connections, because they use dissimilar metals, stainless steel, copper, tin, aluminum, are subject to galvanic corrosion. Corrosion increases the resistance of the connection. This increases the heat generated by current flow through it.

At some current/heat level, the junction of the terminal goes into thermal runaway where it gets hot, the resistance goes up, it gets hotter, increasing the resistance, and the result is a “blown” terminal. The terminal melts and sometimes blows explosively. The battery cell is still perfectly operational, but the terminal has blown off the cell and in some cases taking cell casing with it.

This entire process is exacerbated by two things in the automotive environment. Vibration and thermal cycling. Vibration occurs in aany craft going on the water on a continuous basis and at a number of harmonic frequencies. Low frequency vibrations cause the cells to jostle vertically and this action causes the battery straps to pry up and down on the terminal bolts, stressing the connection. Higher frequency vibrations simply tend to stress the bolt/thread interface, causing bolts to back out and loosen. Thermal cycling is also a problem. Each time you press the accelerator, this increases the power draw and current from the batteries. This heats the connection. As soon as you take your foot off the accelerator, the current demand is decreased, causing an immediate cooling of the connection. This is repeated hundreds of times on even a short drive. Seasonally ambient temperatures of course vary as well and there are temperature variations even from day to night in the same season. All of this works to loosen the terminal connection.

So Please Check your terminal connections and keep them in tip top condition.